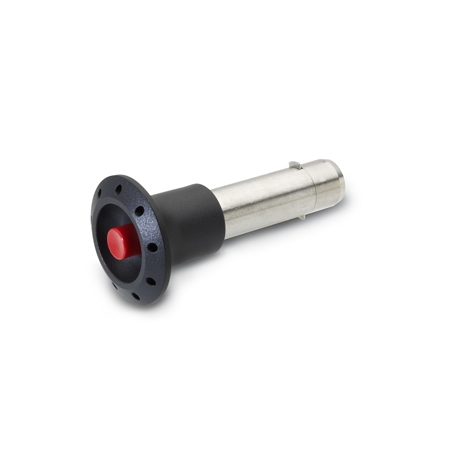

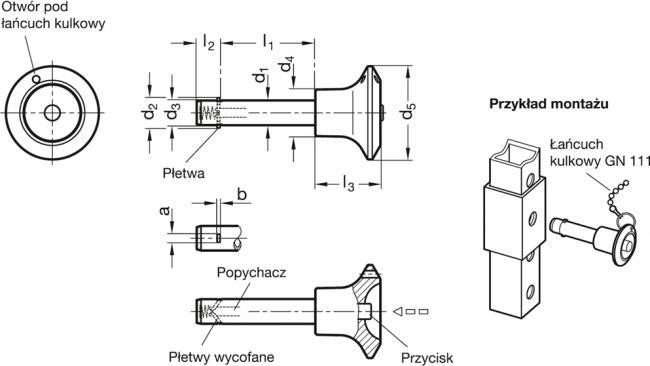

Trzpienie montażowe z blokadą GN 114.3

Materiał

Stal nierdzewna AISI 303.

Płetwy

Stal nierdzewna AISI 304.

Sprężyna

Stal nierdzewna AISI 301.

Rękojeść

Tworzywo, technopolimer na bazie poliamidu (PA), kolor szaro-czarny.

Przycisk

Tworzywo, technopolimer na bazie poliamidu (PA), kolor szaro-czarny.

Maksymalna temperatura pracy

80 °C.

Właściwości i zastosowania

Trzpienie GN 114.3 stosuje się do szybkiego ustalania lub łączenia przedmiotów obrabianych. Typowe zastosowanie to takie w którym trzpień jest często mocowany i demontowany.

Naciskając przycisk dwie płetwy cofają się (trzpień może być wyciągnięty lub wsunięty).

Prostokątny kształt płetw ze stali nierdzewnej tworzy liniową powierzchnię kontaktową co poprawia wartości osiowej siły ścinającej.

Dane w tabeli poniżej należy skorygować o odpowiedni współczynnik bezpieczeństwa.

| Produkt | d%1%-0.1 | l%1%+0.4 | a [mm] | b | d%2% [mm] | d%3% | d%4% | d5 | l%2% [mm] | l%3% [mm] |

| GN 114.3-20-80 | 20 | 80 | 4.8 | 1.2 | 23 +1 | 19.8 | 25 | 40 | 14.8 | 33 |

| GN 114.3-20-70 | 20 | 70 | 4.8 | 1.2 | 23 +1 | 19.8 | 25 | 40 | 14.8 | 33 |

| GN 114.3-20-60 | 20 | 60 | 4.8 | 1.2 | 23 +1 | 19.8 | 25 | 40 | 14.8 | 33 |

| GN 114.3-20-50 | 20 | 50 | 4.8 | 1.2 | 23 +1 | 19.8 | 25 | 40 | 14.8 | 33 |

| GN 114.3-20-45 | 20 | 45 | 4.8 | 1.2 | 23 +1 | 19.8 | 25 | 40 | 14.8 | 33 |

| GN 114.3-20-40 | 20 | 40 | 4.8 | 1.2 | 23 +1 | 19.8 | 25 | 40 | 14.8 | 33 |

| GN 114.3-20-35 | 20 | 35 | 4.8 | 1.2 | 23 +1 | 19.8 | 25 | 40 | 14.8 | 33 |

| GN 114.3-20-30 | 20 | 30 | 4.8 | 1.2 | 23 +1 | 19.8 | 25 | 40 | 14.8 | 33 |

| GN 114.3-16-80 | 16 | 80 | 4.8 | 1.2 | 19 +1 | 15.9 | 22 | 40 | 14.2 | 32 |

| GN 114.3-16-70 | 16 | 70 | 4.8 | 1.2 | 19 +1 | 15.9 | 22 | 40 | 14.2 | 32 |

| GN 114.3-16-60 | 16 | 60 | 4.8 | 1.2 | 19 +1 | 15.9 | 22 | 40 | 14.2 | 32 |

| GN 114.3-16-50 | 16 | 50 | 4.8 | 1.2 | 19 +1 | 15.9 | 22 | 40 | 14.2 | 32 |

| GN 114.3-16-45 | 16 | 45 | 4.8 | 1.2 | 19 +1 | 15.9 | 22 | 40 | 14.2 | 32 |

| GN 114.3-16-40 | 16 | 40 | 4.8 | 1.2 | 19 +1 | 15.9 | 22 | 40 | 14.2 | 32 |

| GN 114.3-16-35 | 16 | 35 | 4.8 | 1.2 | 19 +1 | 15.9 | 22 | 40 | 14.2 | 32 |

| GN 114.3-16-30 | 16 | 30 | 3.8 | 1.2 | 19 +1 | 15.9 | 22 | 40 | 14.2 | 32 |

| GN 114.3-12-80 | 12 | 80 | 3.8 | 1 | 14 +1 | 11.9 | 18 | 34 | 11.3 | 26 |

| GN 114.3-12-70 | 12 | 70 | 3.8 | 1 | 14 +1 | 11.9 | 18 | 34 | 11.3 | 26 |

| GN 114.3-12-60 | 12 | 60 | 3.8 | 1 | 14 +1 | 11.9 | 18 | 34 | 11.3 | 26 |

| GN 114.3-12-50 | 12 | 50 | 3.8 | 1 | 14 +1 | 11.9 | 18 | 34 | 11.3 | 26 |

| GN 114.3-12-45 | 12 | 45 | 3.8 | 1 | 14 +1 | 11.9 | 18 | 34 | 11.3 | 26 |

| GN 114.3-12-40 | 12 | 40 | 3.8 | 1 | 14 +1 | 11.9 | 18 | 34 | 11.3 | 26 |

| GN 114.3-12-35 | 12 | 35 | 3.8 | 1 | 14 +1 | 11.9 | 18 | 34 | 11.3 | 26 |

| GN 114.3-12-30 | 12 | 30 | 3.8 | 1 | 14 +1 | 11.9 | 18 | 34 | 11.3 | 26 |

| GN 114.3-12-25 | 12 | 25 | 3.8 | 1 | 14 +1 | 11.9 | 18 | 34 | 11.3 | 26 |

| GN 114.3-10-60 | 10 | 60 | 3.3 | 1 | 12 +1 | 9.9 | 18 | 34 | 9.8 | 26 |

| GN 114.3-10-50 | 10 | 50 | 3.3 | 1 | 12 +1 | 9.9 | 18 | 34 | 9.8 | 26 |

| GN 114.3-10-45 | 10 | 45 | 3.3 | 1 | 12 +1 | 9.9 | 18 | 34 | 9.8 | 26 |

| GN 114.3-10-40 | 10 | 40 | 3.3 | 1 | 12 +1 | 9.9 | 18 | 34 | 9.8 | 26 |

| GN 114.3-10-35 | 10 | 35 | 3.3 | 1 | 12 +1 | 9.9 | 18 | 34 | 9.8 | 26 |

| GN 114.3-10-30 | 10 | 30 | 3.3 | 1 | 12 +1 | 9.9 | 18 | 34 | 9.8 | 26 |

| GN 114.3-10-25 | 10 | 25 | 3.3 | 1 | 12 +1 | 9.9 | 18 | 34 | 9.8 | 26 |

| GN 114.3-10-20 | 10 | 20 | 3.3 | 1 | 12 +1 | 9.9 | 18 | 34 | 9.8 | 26 |

| GN 114.3-8-50 | 8 | 50 | 2.8 | 0.6 | 10 +0.5 | 7.9 | 15 | 30 | 8.4 | 21 |

| GN 114.3-8-45 | 8 | 45 | 2.8 | 0.6 | 10 +0.5 | 7.9 | 15 | 30 | 8.4 | 21 |

| GN 114.3-8-40 | 8 | 40 | 2.8 | 0.6 | 10 +0.5 | 7.9 | 15 | 30 | 8.4 | 21 |

| GN 114.3-8-35 | 8 | 35 | 2.8 | 0.6 | 10 +0.5 | 7.9 | 15 | 30 | 8.4 | 21 |

| GN 114.3-8-30 | 8 | 30 | 2.8 | 0.6 | 10 +0.5 | 7.9 | 15 | 30 | 8.4 | 21 |

| GN 114.3-8-25 | 8 | 25 | 2.8 | 0.6 | 10 +0.5 | 7.9 | 15 | 30 | 8.4 | 21 |

| GN 114.3-8-20 | 8 | 20 | 2.8 | 0.6 | 10 +0.5 | 7.9 | 15 | 30 | 8.4 | 21 |