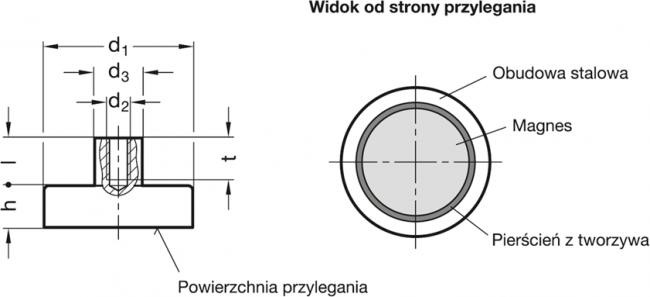

Magnesy GN 50.2

Specyfikacja

Płaskie z gwintem wewnętrznym.

Obudowa / tuleja gwintowana ze stali ocynkowanej.

Materiał magnetyczny

- Twardy ferryt HF, odporność temperaturowa do 200°C.

- Samar, kobalt SmCo SC, odporność temperaturowa do 200°C.

- Neodym, żelazo, bor NdFeB ND, odporność temperaturowa do 80°C.

Właściwości i zastosowania

Magnesy trwałe typu GN 50.2 stanowią ekranowane

układy magnetyczne.

| Produkt | d%1% | h | d%2% [mm] | d%3% | l | t |

| GN 50.2-SC-8-M3 | 8 ±0.1 | 4.5 ±0.1 | M 3 | 6 ±0.1 | 7 | 6 |

| GN 50.2-SC-6-M3 | 6 ±0.1 | 4.5 ±0.1 | M 3 | 6 ±0.1 | 7 | 6 |

| GN 50.2-SC-32-M5 | 32 ±0.1 | 7 ±0.2 | M 5 | 10 ±0.2 | 8.5 | 8 |

| GN 50.2-SC-25-M4 | 25 ±0.1 | 7 ±0.2 | M 4 | 8 ±0.2 | 7 | 7 |

| GN 50.2-SC-20-M4 | 20 ±0.1 | 6 ±0.1 | M 4 | 8 ±0.2 | 7 | 7 |

| GN 50.2-SC-16-M4 | 16 ±0.1 | 4.5 ±0.1 | M 4 | 6 ±0.1 | 7 | 6 |

| GN 50.2-SC-13-M3 | 13 ±0.1 | 4.5 ±0.1 | M 3 | 6 ±0.1 | 7 | 6 |

| GN 50.2-SC-10-M3 | 10 ±0.1 | 4.5 ±0.1 | M 3 | 6 ±0.1 | 7 | 6 |

| GN 50.2-ND-8-M3 | 8 ±0.1 | 4.5 ±0.1 | M 3 | 6 ±0.1 | 7 | 6 |

| GN 50.2-ND-6-M3 | 6 ±0.1 | 4.5 ±0.1 | M 3 | 6 ±0.1 | 7 | 6 |

| GN 50.2-ND-32-7-M5 | 32 ±0.1 | 7 ±0.2 | M 5 | 10 ±0.2 | 8.5 | 8 |

| GN 50.2-ND-25-M4 | 25 ±0.1 | 7 ±0.2 | M 4 | 8 ±0.2 | 7 | 7 |

| GN 50.2-ND-20-M4 | 20 ±0.1 | 6 ±0.1 | M 4 | 8 ±0.2 | 7 | 7 |

| GN 50.2-ND-16-M4 | 16 ±0.1 | 4.5 ±0.1 | M 4 | 6 ±0.1 | 7 | 6 |

| GN 50.2-ND-13-M3 | 13 ±0.1 | 4.5 ±0.1 | M 3 | 6 ±0.1 | 7 | 6 |

| GN 50.2-ND-10-M3 | 10 ±0.1 | 4.5 ±0.1 | M 3 | 6 ±0.1 | 7 | 6 |

| GN 50.2-HF-80-18-M10 | 80 +0.3/0.1 | 18+0.5/-0.2 | M 10 | 20 ±0.2 | 16 | 15 |

| GN 50.2-HF-63-14-M8 | 63 +0.3/-0.1 | 14 +0.5/-0.2 | M 8 | 15 ±0.2 | 16 | 14 |

| GN 50.2-HF-50-M6 | 50 +0.2/-0.1 | 10 +0.4/-0.2 | M 6 | 12 ±0.2 | 12 | 10 |

| GN 50.2-HF-40-8-M5 | 40 +0.2/-0.1 | 8 +0.3/-0.2 | M 5 | 10 ±0.2 | 10 | 8 |

| GN 50.2-HF-32-M4 | 32 ±0.1 | 7 +0.3/-0.2 | M 4 | 8 ±0.2 | 8 | 7 |

| GN 50.2-HF-25-7-M4 | 25 ±0.1 | 7 +0.3/-0.2 | M 4 | 8 ±0.2 | 8 | 7 |

| GN 50.2-HF-20-M3 | 20 ±0.1 | 6 +0.2/-0.1 | M 3 | 6 ±0.1 | 7 | 5 |

| GN 50.2-HF-16-4,5-M3 | 16 ±0.1 | 4.5 +0.2/-0.1 | M 3 | 6 ±0.1 | 7 | 5 |

| GN 50.2-HF-125-M14 | 125 +0.5/-0.1 | 26+0.5/-0.2 | M 14 | 25 ±0.2 | 24 | 20 |

| GN 50.2-HF-10-M3 | ||||||

| GN 50.2-HF-100-M12 | 100 +0.5/-0.1 | 22+0.5/-0.2 | M 12 | 22 ±0.2 | 21 | 18 |

| GN 50.2-HF-10-4,5-M3 | 10 ±0.1 | 4.5 +0.2/-0.1 | M 3 | 6 ±0.1 | 7 | 5 |

| GN 50.2-HF-13-4,5-M3 | 13 ±0.1 | 4.5 +0.2/-0.1 | M 3 | 6 ±0.1 | 7 | 5 |

| GN 50.2-HF-36-M4 | 36 +0.2/-0.1 | 7.7 +0.3/-0.2 | M 4 | 8 ±0.2 | 8.3 | 7 |

| GN 50.2-HF-40-M4 | 40 +0.2/-0.1 | 8 +0.3/-0.2 | M 4 | 8 ±0.2 | 8.5 | 7 |

| GN 50.2-HF-47-M4 | 47 +0.2/-0.1 | 9 +0.4/-0.2 | M 4 | 8 ±0.2 | 8 | 7 |

| GN 50.2-HF-47-M6 | 47 +0.2/-0.1 | 9 +0.4/-0.2 | M 6 | 12 ±0.2 | 11.5 | 10 |

| GN 50.2-HF-50-M4 | 50 +0.2/-0.1 | 10 +0.4/-0.2 | M 4 | 8 ±0.2 | 8.5 | 7 |

| GN 50.2-HF-57-M4 | 57 +0.2/-0.1 | 10.5 +0.5/-0.2 | M 4 | 8 ±0.2 | 8 | 7 |

| GN 50.2-HF-57-M6 | 57 +0.2/-0.1 | 10.5 +0.5/-0.2 | M 6 | 12 ±0.2 | 12 | 10 |

| GN 50.2-HF-63-M4 | 63 +0.3/-0.1 | 14 +0.5/-0.2 | M 4 | 8 ±0.2 | 8 | 7 |

| GN 50.2-HF-80-M6 | 80 +0.3/0.1 | 18+0.5/-0.2 | M 6 | 12 ±0.2 | 10.5 | 10 |

| GN 50.2-ND-40-M6 | 40 +0.2/-0.1 | 8 ±0.2 | M 6 | 10 ±0.2 | 10 | 8 |

| GN 50.2-ND-47-M6 | 47 +0.2/-0.1 | 9.2 ±0.2 | M 6 | 12 ±0.2 | 11.3 | 10 |