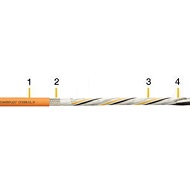

Serwoprzewód CF280.UL.H PUR

1. With pressure extruded, oil-resistant PUR mixture

2. Bending-resistant braided copper shield

3. Power cores with stranded controls and high tensile-strength elements

4. Bending-resistant conductor

- for medium loads

- PUR outer jacket

- shielded

- Oil and coolant-resistant

- Notch-resistant

- Flame retardant

- Hydrolysis and microbe-resistant

- PVC and halogen-free

Classification of the Chainflex® cable:

Class 4.2.3.1

Stressing capacity:

4: Cables with special structure for continuous movement in e-chains®, medium stressing, radii from 7.5 x d, speed up to 3 m/s

Travel distance:

2: Travel up to 10 m

Oil resistance:

3: Oil resistant (in accordance with DIN EN 50363-10-2)

Note: The mentioned external diameters are maximum values and may tend toward lower tolerance limits.

Dynamic information |

||

| Bend radius | e-chain® min. 10 x d flexible min. 8 x d fixed min. 5 x d |

|

| Temperature range | e-chain® -25°C to +80 °C flexible -40°C to +80°C (based on EN 60811-504) fixed -50°C to +80°C (based on DIN EN 50305) |

|

| v max. | Unsupported 10 m/s gliding 2 m/s |

|

| a. max. | 50 m/s² | |

| Length of travel | Unsupported travel and up to 10m gliding applications, Class 2 |

|

Cable structure |

||

| Conductor | Stranded conductor in bending-resistant version consisting of bare copper wires (following EN 60228) Single core: Conductor cable consisting of pre-leads (following EN 60228) |

|

| core insulation | Mechanically high-quality, especially low capacitance TPE mixture. | |

| Core structure | Power cores with control pair elements stranded with elements for high tensile stresses. | |

| Core identification | Power cores: Black cores with white numbering, one core green-yellow 1. Core: U / L1 / C / L+ 2. Core: V / L2 3. Core: W / L3 / D / L- Control pair: Black cores with white numbering. 1. Control core: 5 2. Control core: 6 Bus element: white, blue |

|

| Element shield | Bend-resistant braiding made of tinned copper wires. Coverage approx. 55% linear, approx. 80% optical. |

|

| Intermediate layer | Foil taping over the external layer | |

| Overall shield | Bend-resistant braiding made of tinned copper wires. Coverage approx. 55% linear, approx. 80% optical. |

|

| Outer jacket | Low-adhesion mixture on PUR base, adapted to suit the requirements in e-chains® (according to DIN VDE 0282 Part 10). Colour: Pastel orange (similar to RAL 2003) |

|

Electrical information |

||

| Nominal voltage | 600/1000 V (following DIN VDE 0250) | |

| Testing voltage | 4000 V (following DIN EN 50396) | |

Properties and approvals |

||

| UV resistance | Medium | |

| Oil resistance | Oil-resistant (following DIN EN 50363-10-2), Class 3 | |

| Offshore | MUD-resistant following NEK 606 - status 2009 | |

| Flame retardant | According to IEC 60332-1-2, CEI 20-35, FT1, VW-1 | |

| Silicone-free | Free from paint-wetting impairment substances (according to PV 3.10.7 – status 1992). | |

| Halogen-free | Following EN 50267-2-1 | |

| UL/CSA | Style 10989 and 21223, 1000 V, 80 °C Spindle cable/Single core: Style 10492 and 10973, 1000 V, 80 °C |

|

| NFPA | Following NFPA 79-2012 chapter 12.9 | |

| EAC | Certified according to no. TC RU C-DE. ME77.B.01255 | |

| CTP | Certified according to No. C-DE. PB49.B.00420 | |

| CEI | Following CEI 20-35 | |

| Lead free | Following 2011/65/EC (RoHS-II) | |

| Clean room | According to ISO Class 1. Outer jacket material complies with CF27.07.05.02.01.D, tested by IPA according to standard 14644-1. |

|

| DESINA | According to VDW, DESINA standardisation | |

| CE | Following 2014/35/EU | |

| Guaranteed service life for this series according to the guarantee conditions | |||||||

|---|---|---|---|---|---|---|---|

| Double strokes* | 5 million | 7,5 million | 10 million | ||||

| Temperature | v max. [m/s] | a. max. | Length of travel | R min. | R min. | R min. | |

| from/to [°C] | unsupported | gliding | m/s² | [m] | [factor x d] | [factor x d] | [factor x d] |

| -25 / -15 | 10 | 2 | 50 | ≤10 | 12,5 | 13,5 | 14,5 |

| -15 / +70 | 10 | 11 | 12 | ||||

| +70 / +80 | 12,5 | 13,5 | 14,5 | ||||

* Higher number of double strokes possible - please ask for your individual calculation.

Typical application areas

- for medium loads

- almost unlimited resistance to oil

- Indoor and outdoor applications without direct solar radiation

- Unsupported travel distances and up to 10 m for gliding applications

- Machining units/machine tools, low temperature applications