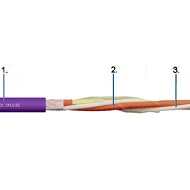

Światłowód chainflex® CFLG.EC PVC

1. Highly abrasion-resistant PUR jacket mixture

2. Reinforced optical fibres stranded with optimised pitch length

3. FOC cores stranded with high-tensile aramide fibres

- Graded glass-fibre cable for heavy duty applications

- PVC outer jacket

- oil resistant

- Flame retardant

Classification of the Chainflex® cable:

Class 4.2.2.1

Stressing capacity:

4: Cables with special structure for continuous movement in e-chains®, medium stressing, radii from 7.5 x d, speed up to 3 m/s

Travel distance:

2: Travel up to 10 m

Oil resistance:

2: Oil resistant (in accordance with DIN EN 50363-4-1)

Note: The mentioned external diameters are maximum values and may tend toward lower tolerance limits.

Dynamic information |

||

| Bend radius | e-chain® min. 7,5 x d flexible min. 6 x d fixed min. 4 x d |

|

| Temperature | e-chain® +5°C to +70°C flexible -5°C to +70°C (based on EN 60811-504) fixed -15°C to +70°C (based on DIN EN 50305) |

|

| v max. | Unsupported 3 m/s gliding 2 m/s |

|

| a. max. | 20 m/s² | |

| Length of travel | Unsupported travel distances up to 10 m for gliding applications, Class 2 | |

Cable structure |

||

| Fibre optic cables | 50/125 μm, 62.5/125 μm special fixed wire elements with aramide strain relief. |

|

| Core structure | FOC cores stranded with high-tensile aramide dampers with especially short pitch length. |

|

| Core identification | FOC cores: Orange or blue with black numerals | |

| Outer jacket | Low adhesion, oil-resistant mixture on PVC base (according to DIN VDE 0281 Part 13) suited for e-chain® requirements. Colour: Red lilac (similar to RAL 4001) |

|

Properties and approvals |

||

| Oil | Oil resistant (according to DIN EN 50363-4-1), Class 2. | |

| Flame retardant | According to IEC 60332-1-2 | |

| Silicone-free | Free from silicone which can affect paint adhesion (following PV 3.10.7 – status 1992) | |

| Lead free | Following 2011/65/EC (RoHS-II) | |

| Clean room | According to ISO Class 1. Outer jacket material complies with CF240.02.24, tested by IPA according to standard 14644-1. |

|

| CE | Following 2014/35/EU | |

| Guaranteed service life for this series according to the guarantee conditions | |||||||

|---|---|---|---|---|---|---|---|

| Double strokes* | 5 million | 7,5 million | 10 million | ||||

| Temperature | v max. [m/s] | a. max. | Length of travel | R min. | R min. | R min. | |

| from/to [°C] | unsupported | gliding | m/s² | [m] | [factor x d] | [factor x d] | [factor x d] |

| +5 / +15 | 3 | 2 | 20 | ≤10 | 10 | 11 | 12 |

| +15 / +60 | 7,5 | 8,5 | 9,5 | ||||

| +60 / +70 | 10 | 11 | 12 | ||||

* Higher number of double strokes possible.

Typical application areas

PHASE-OUT MODEL

This series will be replaced by

CFLG88

- for high load requirements

- light oil influence

- preferably indoor applications, but also outdoor ones at temperatures > 5 °C

- Unsupported travel distances and up to 10 m for gliding applications

- Storage and retrieval units for high-bay warehouses, machining units/packaging machines, quick handling, indoor cranes, printer